Content provided by Those Classic Trains

Regardless of your mode of travel, moving at high speed is dangerous. This is especially true on a railroad, where trains are guided on fixed courses, cannot steer around each other, and are dispatched by remote control. While railroads are the safest form of public transportation (due to the extensive operating rules and the military discipline they operate under), wreaks do happen on occasion.

There were several well publicized disasters in the 19th century- notably the Ashtabula Horror, in which a bridge collapsed under a train, the cars were smashed and caught fire with grievous loss of life. Due partly to public outcry, partly to legislation, and partly to genuine concern by the industry, railroad safety has always been a high priority.

The evolution of the steel carbody was caused by these concerns and in part provided the long sought solution. When Pullman began researching all steel construction in the 1900s, what emerged was a radical evolution in carbody design.

The very first steel sleeper, the "Johnstown", built in 1907, is based on the stock Plan 1963 Varnish 12-1 sleeper, which was faithfully copied in its styling and appointments. Under the skin, however, this is not just another pretty face.

One development of the late Varnish age had been the cast steel buffer-and-bolster assemblies built into the outboard ends of each car. These proved to be highly impact resistant, while the wood construction between them would collapse. Ideally, the center part of the carbody should remain intact while the ends would crush to absorb the impact (rather than the reverse). So in place of the traditional truss rods, the "Johnstown" has a massive plate steel box girder- 2' wide, nearly 30" deep and over 83' long.

This girder frame is designed to support the passenger cabin as a rigid unit. On this solid deck are added heavy formed steel corner posts just inside the doorways. (One thing to look out for is that equipment drawings list the length over these corner posts - but not including the vestibules.) Between these, a box truss is built of formed steel riveted together with a 16 gauge steel skin overall.

The vestibules are of lighter (although still substantial) construction, which makes them into crush zones - helped along by the 1/2" thick diaphragm plates which act as a rigid battering ram to spread collision forces across the end of the car. The result was a whopping increase in car weight - from 50 tons to over 80 tons - and a carbody that could withstand just about anything.

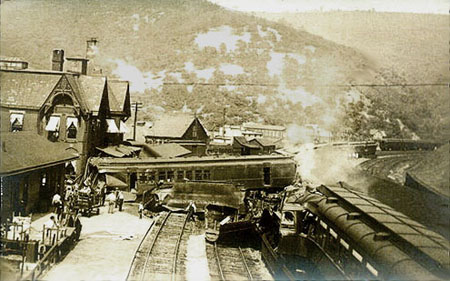

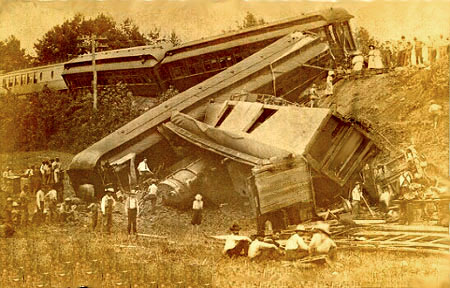

These two photos graphically illustrate these advances in carbody construction and the greater safety it provides.

Here we see the aftermath of an ugly head-on collision at Tyrone, Pennsylvania in the mid 1920s. You can see from how the cars were tossed about that the two trains must have collided at high speed, yet both cars in this picture are relatively intact. (Note that the locomotive disintegrated: the curved piece of sheet metal on the center track is the cab roof while the large piece behind it is part of the tender).

Note how, on both the baggage-club in the background and the Gothic sleeper in the foreground, the vestibules crushed: absorbing the force of the impact. The main carbodies, supported by the massive underframe girders and protected by the carbody vertical sills, are still in fair condition.

Now compare the cars above to this photo of a derailment near Midway, Tennessee in 1909. Here the train left the rails and tumbled down an embankment: a serious wreak, true, but nowhere near as bad as the head-on above.

You can see, however, that the carbodies themselves have broken. The baggage car in the foreground has broken up into it's major components (see how the roof has detached as a unit) while the Varnish sleeper on the embankment is twisted out of shape.

If the Gothic cars in the first photo had been in the Tennessee wreak, they would have soon been repaired and returned to service. However, had the Varnish cars in the second photo been at Tyrone, they would have been smashed to kindling.

The "Johnstown" of 1907 was a conceptual breakthrough in car design. Over the next couple of years, Pullman refined the original concept. Mass production began in 1910 with an eventual total of over 10,000 cars built before the Great Depression. What the "Johnstown" started would soon be improved upon with better brakes, more stable trucks and finally stainless steel construction. With these cars, the day of fast, comfortable and, most especially, safe passenger travel had arrived.

| Home Site Map Search Contact |

North East Rails © Clint Chamberlin. |